Products / Automatic Tool Clamping

HSK

the standard interface

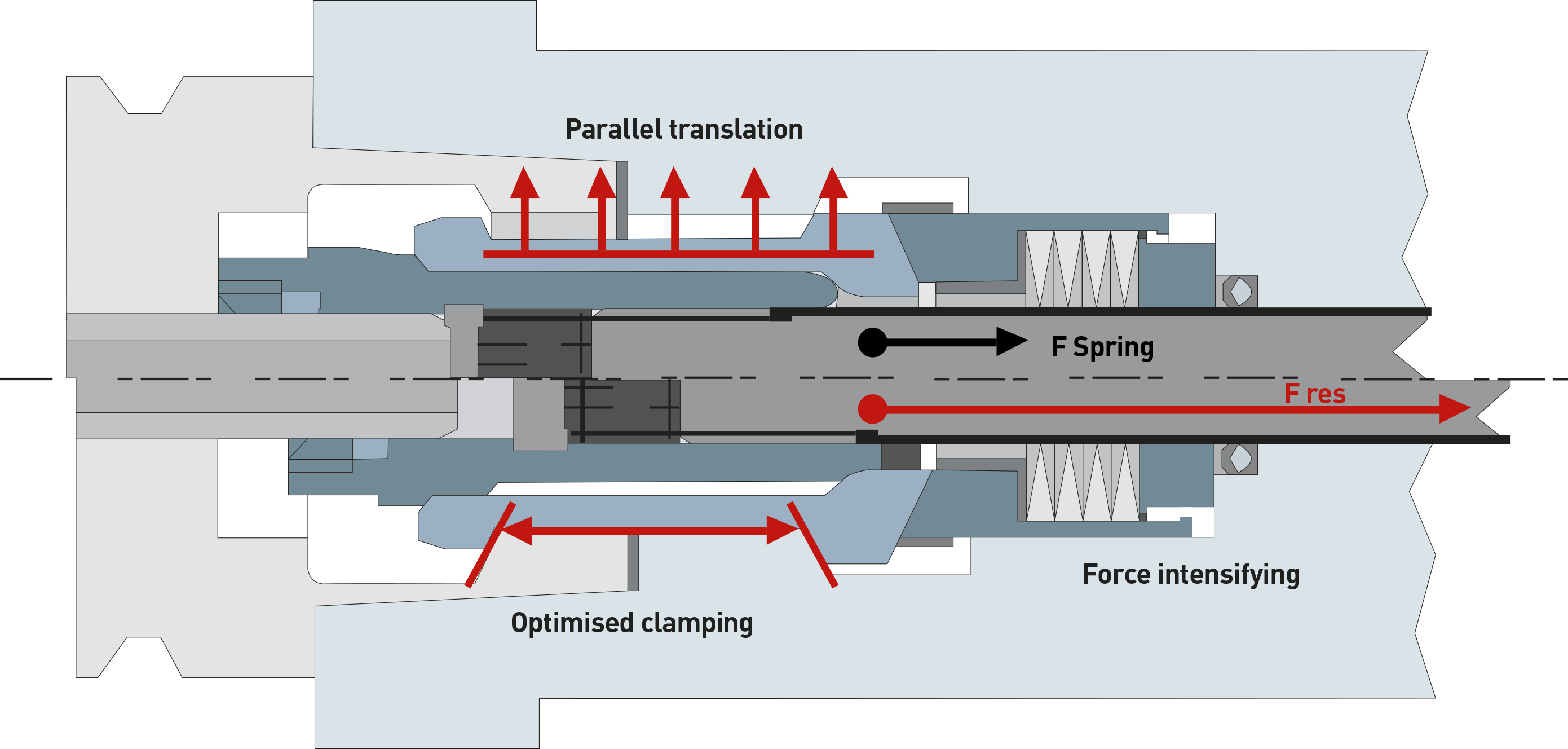

A development of the steep taper, HSK was created as part of a research project carried out by RWTH Aachen University in close collaboration with well-known industrial partners. From the outset, OTT-JAKOB played a leading role in the creation of the HSK interface.

Since its standardisation, HSK has become a standard interface in machine tool technology. With the congruence between the flange and taper contact surfaces, the HSK clamping system is ideal for highly precise machining results and a repeat accuracy on the micro scale.

The hollow-shaft taper (HSK) has a shorter, lighter structure than the steep taper, which allows tools to be changed more quickly and higher speeds to be reached. By virtue of its high pull-in forces, excellent stiffness and optimal torque transmission, HSK is also ideal for use in heavy machining.